Image 1 of 2

Image 1 of 2

Image 2 of 2

Image 2 of 2

Amaco Potters Choice PC-16 Purple Crystal

Purple Crystal is a matte violet glaze for Cone 5 that becomes glossy deep indigo with purple crystal floats at Cone 6.

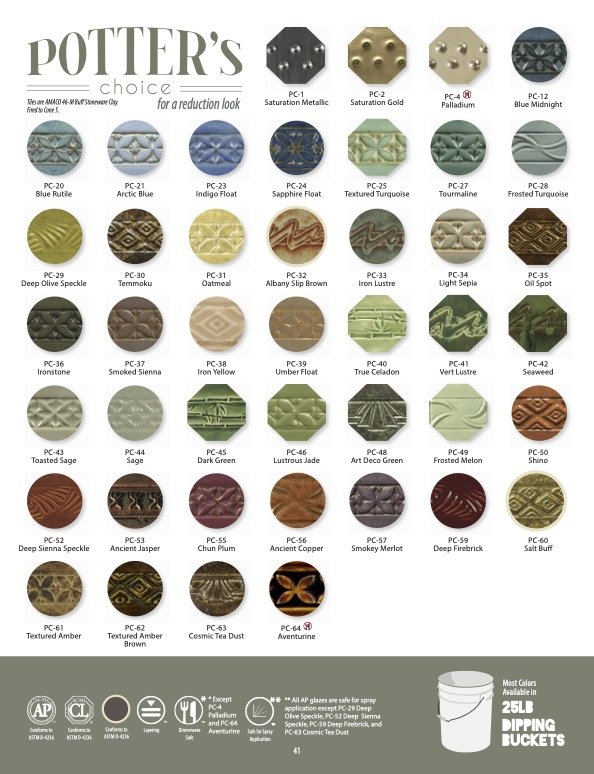

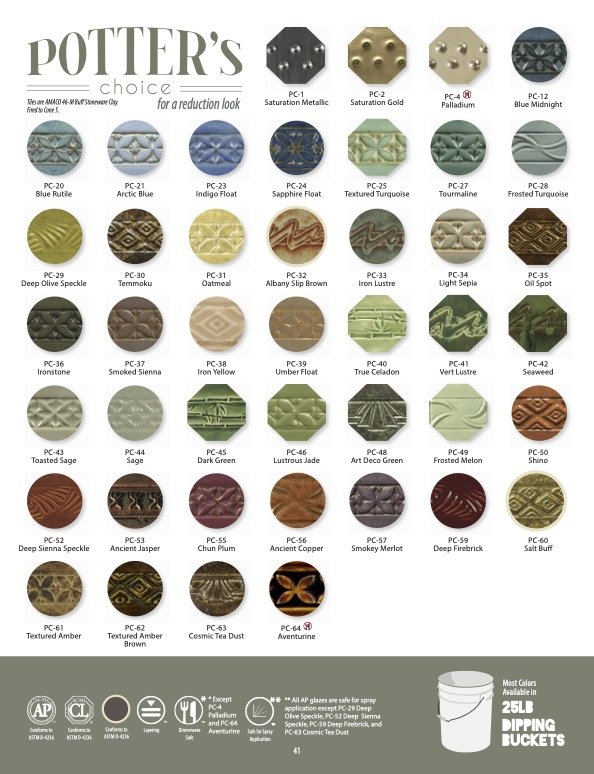

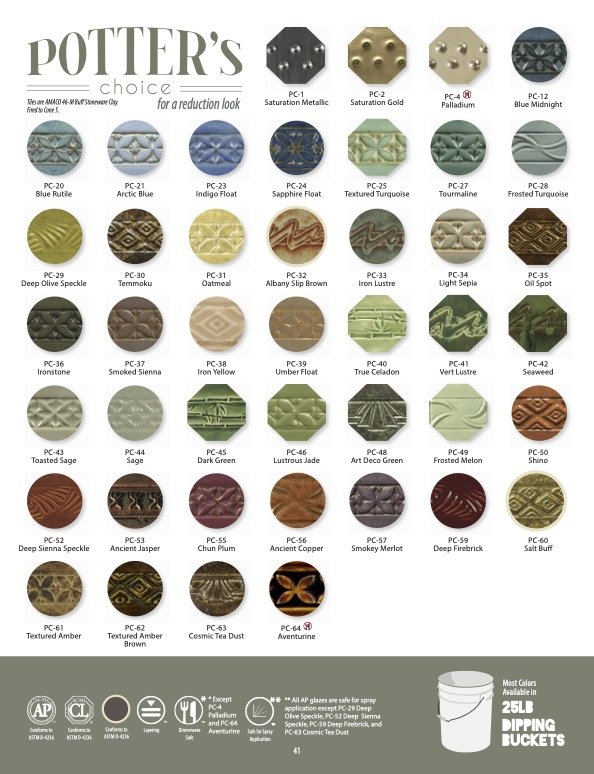

(PC) Potter's Choice

The Potter's Choice glaze series was designed with the potter in mind! These stunning glazes add fluid colors and effects to smooth or textured ware, with optimal results at Cone 5/6. To use these glazes is to step into different ceramic glaze traditions of many cultures throughout history. Check out our PC Layering charts to see all the amazing results you can try in your own studio!

•Reduction Effects in Oxidation

•Variety of Colors and Surfaces

•Cone 5 - 6

•Limitless Layering Combinations!

Cone 5 = 1184°C (at 150°C/hour for the final 100°C of firing) / 2201°F ( at 270°F/hour in the final 200°F of firing)

Cone 6 = 1241°C (at 150°C/hour for the final 100°C of firing) / 2266°F ( at 270°F/hour in the final 200°F of firing)

Purple Crystal is a matte violet glaze for Cone 5 that becomes glossy deep indigo with purple crystal floats at Cone 6.

(PC) Potter's Choice

The Potter's Choice glaze series was designed with the potter in mind! These stunning glazes add fluid colors and effects to smooth or textured ware, with optimal results at Cone 5/6. To use these glazes is to step into different ceramic glaze traditions of many cultures throughout history. Check out our PC Layering charts to see all the amazing results you can try in your own studio!

•Reduction Effects in Oxidation

•Variety of Colors and Surfaces

•Cone 5 - 6

•Limitless Layering Combinations!

Cone 5 = 1184°C (at 150°C/hour for the final 100°C of firing) / 2201°F ( at 270°F/hour in the final 200°F of firing)

Cone 6 = 1241°C (at 150°C/hour for the final 100°C of firing) / 2266°F ( at 270°F/hour in the final 200°F of firing)